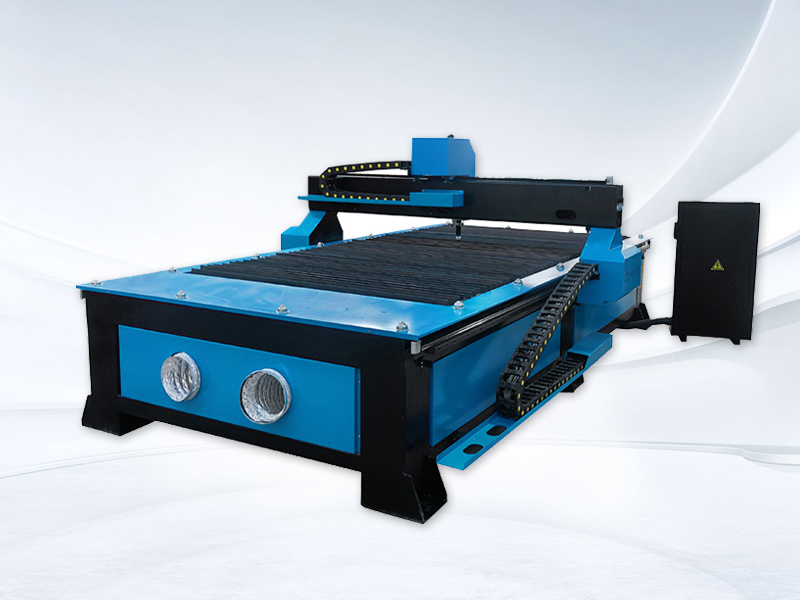

A : The structure and configuration list

1. seamless welding machine body

2. 1500*3000mm working area

3. Independent control cabinet

4. STARfire control system

5. Automatic Torch height controller

6. Starcam software

7. 2GB processing file

8. high precision square guide rail

9. LGK105A Plasma

10.China high precision stepper motor

11.Multi-function tool box

12.Efficiency exhaust smoke system

13.Easy feeding slide material system

14.High quality soft electricity cable can be bend for 1.5 million times

15.15 sets of nozzle electrodes

16.All the necessary parts for machine working

B :The main parts photo

C : The Technical parameter

D : The sample photos by this machine

E : The advantages of our machine

①We do this line many years, have rich experience and professional knowledge, will let you get the most suitable machine with the right configuration. This ability can let you avoid many mistake and avoid some trouble. Other factory usually lack this experience, and bring some trouble for the real customer.

②If use the plasma cutting machine to cut the the thick meal, have to use the arc height adjust system, while our height adjust system use the high sensor, one minute can send out 12,000 signal per minute, while other height adjust system usually send out 10000 signal per minute, so our cutting quality more better than other factory and cutting speed a litter faster than the same power plasma source.

③we equipped the two fan for take the cutting smoke out from the room, front fan will blow to back, the back fan will exhaust the smoke out from the machine and out from the room. This way, will efficiency to let the workshop in the good environment. While other factory does not have this fan or only have one.

④ All our machines have to be checked three times, then allow to send out ,and finally will put one 8GB flash disk into the package, when the customer received the machine, can easy check the video from the 8GB flash disk ,then do the easy operation, in the video nearly like hand by hand do the teaching job, so can let the customer in the shot time to let the machine create the profit. While we also have the video platform, after you purchase the machine, we will give you one password, then you can easy to get the efficiency “after-sell service” from the internet. While other small factory usually, only check one time for the machine, and no 8GB flash disk, and no video platform, then it is hard for you to get the good after-sell service.

⑤ The painting: all our machine body have been processed by professional anti-rust treatment. First, we spray 2 times anti-rust paint to ensure that all parts of the machine in a fully protected state, and then spray color. This can effectively prevent the machine rust, resulting in damage to the machine. Other manufacturers do not take anti-rust treatment or only spay 1 time rust paint.

⑥ Just because our machine all equipped the professional parts, and test more seriously for the whole machine, so our guarantee period it is 2 years, while other factory it is only 1 years.

⑦ we will free provide 2G processing design (USD 320) and Australia professional metal cutting software for you, in the 2G processing design have thousand beautiful graphic, after you get the machine, you can let the machine do a lot of beautiful work, while no need find the engineer to help you to design.

⑧ Machine structure is designed by famous mechanical professor, to add many columns for each bean. So that the machine body can bear more weight for large, thick metal sheets without deforming. But some small factories will not add these parts for saving cost, their machine is easy to deform for thick metal.

E : Factory model display

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8615653328535

WhatsApp:+8615653328535 Wechat: +8615965331535

Wechat: +8615965331535  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com