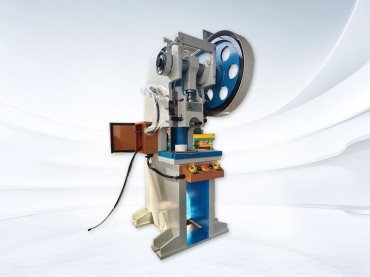

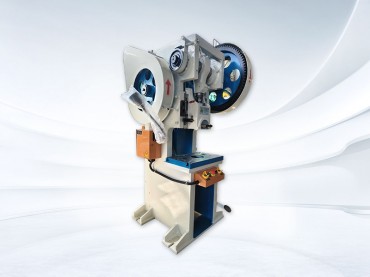

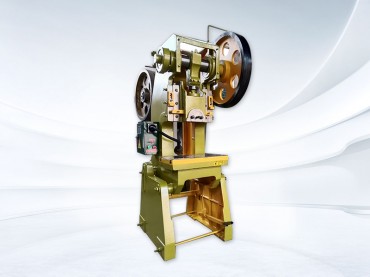

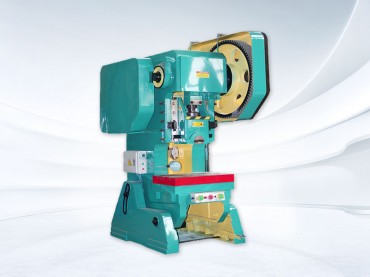

一、JH21-160T Punch press

二、Main parameters of machine tools

三、 Performance and structure

Pneumatic punching machine is an efficient and low consumption processing equipment, which can perform jog, inch, continuous, single action and other actions when working with a pneumatic friction clutch. And it can emergency brake, with standard photoelectric protection, which can effectively protect personal safety. The electrical equipment is equipped with PLC control and electronic cam controller, which can be freely connected to other peripheral devices. The technology of stamping, forming, cutting, stretching and other processes for metal and non-metal materials is widely used in mechanical manufacturing industries such as automobiles, aviation, hardware, electrical appliances, and light industry due to its unique advantages, and occupies an important position.

Pneumatic punching machine is an efficient and low consumption processing equipment, which can perform jog, inch, continuous, single action and other actions when working with a pneumatic friction clutch. And it can emergency brake, with standard photoelectric protection, which can effectively protect personal safety. The electrical equipment is equipped with PLC control and electronic cam controller, which can be freely connected to other peripheral devices. The technology of stamping, forming, cutting, stretching and other processes for metal and non-metal materials is widely used in mechanical manufacturing industries such as automobiles, aviation, hardware, electrical appliances, and light industry due to its unique advantages, and occupies an important position.

1. Body

The body is a welded structure, with the crankshaft supported in a front and rear integral shaft sleeve. The gears are installed in a closed box of the body with a cover plate, and the box is filled with oil to immerse the gear shaft in the oil. The oil filling height is determined by the oil mark on the left side of the body. The two support plates on the upper left and right inner walls of the fuselage are used to install and fix the electric motor.

2. Transmission

The transmission of this press is driven by an electric motor through a V-belt, friction clutch brake, and transmission gear to rotate the crankshaft. The electric motor is fixed on the support plate through a rubber shock-absorbing pad. The transmission gears are lubricated with immersion oil. There is a crank angle indicator device at the front end of the crankshaft, and an encoder is installed at the tail end of the shaft synchronized with the crankshaft. It synchronously transmits the movement of the crankshaft to the cam control box, thereby issuing various control signals for the operation of the press.

The transmission of this press is driven by an electric motor through a V-belt, friction clutch brake, and transmission gear to rotate the crankshaft. The electric motor is fixed on the support plate through a rubber shock-absorbing pad. The transmission gears are lubricated with immersion oil. There is a crank angle indicator device at the front end of the crankshaft, and an encoder is installed at the tail end of the shaft synchronized with the crankshaft. It synchronously transmits the movement of the crankshaft to the cam control box, thereby issuing various control signals for the operation of the press.

3. Clutch

The press adopts a combination pneumatic dry friction clutch brake. The piston, under the action of spring force, presses the brake friction plate onto the brake friction plate, making the brake in a braking state.  The machine is in standby idle mode. When compressed air enters the cylinder through the air rotary joint, the piston compresses the spring, the brake disengages, and the clutch engages. The slider runs downwards. When compressed air is released through the solenoid valve, under the action of spring force, the clutch disengages and the brake engages. The machine is once again in idle standby mode.

The machine is in standby idle mode. When compressed air enters the cylinder through the air rotary joint, the piston compresses the spring, the brake disengages, and the clutch engages. The slider runs downwards. When compressed air is released through the solenoid valve, under the action of spring force, the clutch disengages and the brake engages. The machine is once again in idle standby mode.

4. Hydraulic overload safety:

This press slide can be optionally equipped with a hydraulic overload protector. When the press is overloaded, the hydraulic overload valve is opened, the hydraulic cylinder releases pressure, and the system automatically alarms and stops running. The indicator light is on. The overload red signal light is on, the clutch is disengaged, and the brake is applied, thus protecting the machine from damage. After restarting, repeat filling the hydraulic cylinder with oil to normal pressure before continuing to use. The connecting rod of the slider press adopts a split form, and the connecting rod hole is equipped with bearing shells. The height of the machine tool slider mold is manually adjusted using a special wrench. The slider body is a cast as a whole structure, with six sided rectangular guide rails on both sides, placed inside the body guide rails for up and down reciprocating motion. The bottom of the slider has a mold handle hole, and the screw on the front of the slider is used to tighten the mold handle. There is a T-shaped groove on the bottom surface of the slider to secure the large-sized upper template. The lower part of the slider body is equipped with left and right feeding crossbeams for upper feeding.

This press slide can be optionally equipped with a hydraulic overload protector. When the press is overloaded, the hydraulic overload valve is opened, the hydraulic cylinder releases pressure, and the system automatically alarms and stops running. The indicator light is on. The overload red signal light is on, the clutch is disengaged, and the brake is applied, thus protecting the machine from damage. After restarting, repeat filling the hydraulic cylinder with oil to normal pressure before continuing to use. The connecting rod of the slider press adopts a split form, and the connecting rod hole is equipped with bearing shells. The height of the machine tool slider mold is manually adjusted using a special wrench. The slider body is a cast as a whole structure, with six sided rectangular guide rails on both sides, placed inside the body guide rails for up and down reciprocating motion. The bottom of the slider has a mold handle hole, and the screw on the front of the slider is used to tighten the mold handle. There is a T-shaped groove on the bottom surface of the slider to secure the large-sized upper template. The lower part of the slider body is equipped with left and right feeding crossbeams for upper feeding.

5. Balance cylinder (optional)

The punching machine can be equipped with a balance cylinder, which is suspended at the top of the machine body. Its piston rod is connected to the left and right walls of the slider body, which can balance the weight of the slider and the upper mold when using a large mold. Normally, it is not used.

6. Air pipeline system

Compressed air is sent from the left outer wall located at the lower rear of the body. After passing through the air filter, pressure reducing valve, and oil mist eliminator, compressed air enters the air storage cylinder for the clutch balance cylinder and the air storage cylinder for the top mold. The outlet of the clutch air storage cylinder enters the friction clutch cylinder through a dual safety solenoid valve. The outlet of the balance cylinder air storage cylinder leads to the left and right balance cylinders respectively. The clutch air storage cylinder is equipped with a safety valve, and the balance cylinder air storage cylinder is equipped with a safety valve. The condensate inside the air storage cylinder can be discharged by the ball valve.

Compressed air is sent from the left outer wall located at the lower rear of the body. After passing through the air filter, pressure reducing valve, and oil mist eliminator, compressed air enters the air storage cylinder for the clutch balance cylinder and the air storage cylinder for the top mold. The outlet of the clutch air storage cylinder enters the friction clutch cylinder through a dual safety solenoid valve. The outlet of the balance cylinder air storage cylinder leads to the left and right balance cylinders respectively. The clutch air storage cylinder is equipped with a safety valve, and the balance cylinder air storage cylinder is equipped with a safety valve. The condensate inside the air storage cylinder can be discharged by the ball valve.

7. Optoelectronic protection

This machine is equipped with a reliable safety photoelectric protection device, which can emergency stop within any travel range. Effectively protect the workpiece and personal safety.

This machine is equipped with a reliable safety photoelectric protection device, which can emergency stop within any travel range. Effectively protect the workpiece and personal safety.

四、 Machine tool electrical system

The electrical control system of this machine is summarized as follows:

This electrical appliance is controlled by PLC, with a main power supply of 380V, 50Hz, three-phase,

Control power supply: 220V. The main circuit and motor both use automatic switches for short circuit protection and overload protection. The control circuit adopts fuses for short circuit protection.

The main components of the machine are reliably grounded.

五、 Manufacturing standards and usage conditions

The safety performance of this press complies with all the requirements in GB 17120-1997 "Safety Technical Conditions for Forging Machinery" and JB3350-1993 "Safety Technical Requirements for Mechanical Press".

This machine is suitable for any material preparation workshop, and its conditions are:

1. Environmental temperature: -10~+40 ℃ (oil tank temperature should not be lower than+10 ℃)

2. Relative humidity: ≤ 80% (+25 ℃)

3. Power supply: three-phase 380 V ± 10% 50Hz

This machine has no "three wastes" discharged, and the noise limit meets the requirements of JB9969-1999.

六、 Lubrication system

The lubrication system of this press has the following three lubrication methods:

1. Oil pool immersion lubrication:

The transmission gear is immersed in the gearbox of the machine body. When refueling, the top cover of the oil tank can be removed. The oil amount is indicated by the circular oil mark installed on the side of the machine body. There is an oil drain valve at the bottom of the oil tank. When draining, pull off the ball valve and use a wire groove to guide the oil to the recovery device.

The transmission gear is immersed in the gearbox of the machine body. When refueling, the top cover of the oil tank can be removed. The oil amount is indicated by the circular oil mark installed on the side of the machine body. There is an oil drain valve at the bottom of the oil tank. When draining, pull off the ball valve and use a wire groove to guide the oil to the recovery device.

2. Concentrated lubrication with concentrated oil:

There are two types of concentrated oil lubrication, manual pump lubrication and electric pump lubrication. A manual pump is used to lubricate the cylinder guide sleeve, while an electric pump is used to lubricate the body guide rail, crankshaft support, and connecting rod bearing. The concentrated oil pump is installed on the inner wall of the machine body, and the lubricating oil inside the concentrated oil pump is directed to the machine body guide rail, crankshaft support, connecting rod bearing, etc. through the oil separator. Adequate lubrication should be applied before each driving. The manual pump directly supplies oil by pulling the handle of the concentrated oil pump

There are two types of concentrated oil lubrication, manual pump lubrication and electric pump lubrication. A manual pump is used to lubricate the cylinder guide sleeve, while an electric pump is used to lubricate the body guide rail, crankshaft support, and connecting rod bearing. The concentrated oil pump is installed on the inner wall of the machine body, and the lubricating oil inside the concentrated oil pump is directed to the machine body guide rail, crankshaft support, connecting rod bearing, etc. through the oil separator. Adequate lubrication should be applied before each driving. The manual pump directly supplies oil by pulling the handle of the concentrated oil pump

Provide lubrication points for each. The electric oil pump is automatically controlled by the oil pump system.

3. Disperse and lubricate the oil gun.

八、List of random attachments and supporting parts

九、List of random technical documents

If you need punching machines or are interested in punching machines, please provide the tonnage of punching machines or sheet materials, sheet thickness, sheet width, punching diameter, and we will recommend suitable punching machines for you

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8615653328535

WhatsApp:+8615653328535 Wechat: +8615965331535

Wechat: +8615965331535  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com