一、Machine model name:

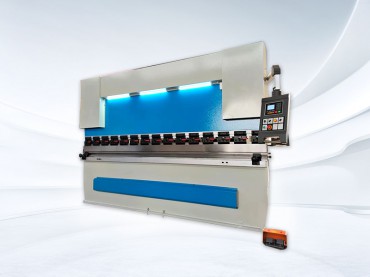

WC67Y-63Tx2500 Hydraulic bending machine

二、Main parameters :

三、 Performance Introduction

Hydraulic sheet metal bending machine is a machine tool controlled by a combination of hydraulic and electrical systems, which is used to perform a one-time bending of sheet metal. It uses a simple mold to press the metal sheet into the desired geometric shape, and can be widely used in electrical, electronic, metal structures, instruments, instruments, and daily use

Industries such as hardware and construction decoration. Assembling different molds can process various workpieces.

四、 Rack section

The rack is composed of left and right pillars, oil tanks, and other workpieces welded into a complete frame, and the workbench is securely connected

Connected to the lower part of the left and right pillars.

五、 Sliding block section

The slider part consists of a slider, an oil cylinder, and a mechanical stopper fine-tuning structure. The slider adopts an integral panel structure, and the left and right oil cylinders are fixed on the frame. The piston (rod) drives the slider through hydraulic pressure

Up and down movement.

The mechanical stopper is externally placed on the top of two oil cylinders, with a compact structure and synchronous adjustment on both sides. When the slider (upper mold) is uneven, stop the slider at the top dead center, disconnect the coupling sleeve of the synchronous transmission shaft on both sides of the mechanical stopper, rotate either side of the worm gear in the upper worm gear box of the left and right oil cylinders (forward or reverse), then press the slider to the bottom dead center, measure and adjust (repeat the above operation) until the slider (upper mold)

Equal the height on both sides, and finally position and install the coupling sleeve.

六、 Synchronous mechanism

A mechanical forced synchronization mechanism composed of a torsion shaft and an arm, with a simple structure and stable performance

Damn it, high synchronization accuracy.

七、 Rear material blocking mechanism

Drive the material blocking frame forward and backward through the front handwheel. The top rod on the rear stopper can rotate around the axis

To prevent damage to the workpiece during bending, the operation is convenient, fast, and the material blocking accuracy is high.

八、 Precision compensation mechanism for bending workpieces

The fine-tuning mechanism is located on the upper mold, used for compensating and fine-tuning the upper and lower parts of the upper mold to ensure the accuracy of the bent workpiece. Sometimes, the bent workpiece has a slight deviation in the full length angle. In order to achieve better consistency in the bending angle, the mold tightening screw can be slightly loosened (note that the upper mold falls off and damages the mold), the inclined wedge block can be moved left and right to perform fine-tuning the upper and lower parts of the upper mold, and then the screw can be tightened and re folded until it reaches full capacity

Until requested.

九、Machine tool electrical system

The electrical control system of this machine is summarized as follows:

Main power supply: 380V, 50Hz, three-phase, control power supply: 24V. The main circuit and each motor are equipped with automatic switches for short circuit protection and overload protection. The control circuit part adopts fuses

Perform short-circuit protection. The main components of the machine are reliably grounded.

This machine has three working modes, which are selected by a universal conversion switch for jog, single, and continuous operation. The machine operation is controlled by a foot switch, which is convenient and fast. This machine is equipped with a power supply and a machine operator

As a status indicator light, the electrical components use China Chint. The circuit is simple, safe, and easy to maintain.

十、Machine tool hydraulic system

The hydraulic system consists of an electric motor, oil pump, valve group, oil tank, oil pipe, and hydraulic accessories. The maximum working pressure of the hydraulic system is 20MPa, which is adjusted by the main circuit system valve. The hydraulic valve is selected from Haimen hydraulic valve, and all sealing components are selected from Japanese Walkar. The pipeline layout is simple and leak proof

Less, convenient maintenance and debugging.

十一Technology and craftsmanship:

1. This machine adopts advanced hydraulic integrated valve blocks. Compact structure reduces pipeline connections,

Improved the reliability and maintainability of the system.

2. The bending machine adopts parallel oil cylinders, and in order to ensure precise positioning of the slider at the bottom dead center, a mechanical blocking mechanism is set inside the oil cylinder, which is manually adjusted. The synchronization of the slider during the stroke is achieved using

Mechanical synchronous mechanism, simple structure, stable and reliable, convenient maintenance.

3. The stroke of the bending machine slider can be adjusted within 0-80mm.

4. The bending machine mold is made of alloy steel through forging, milling, heat treatment and grinding. The upper mold adopts multiple short molds connected together to form a whole long mold, which has high accuracy and good interchangeability.

Easy to load and unload.

十二、Working environment and usage conditions

This machine is suitable for any material preparation workshop, and its conditions are:

1. Environmental temperature: -10~+40 ℃ (oil tank temperature should not be lower than+10 ℃)

2. Relative humidity: ≤ 80% (+25 ℃)

3. Power supply: three-phase 380V ± 10% 50Hz

This machine has no "three wastes" discharged, and the noise limit meets the requirements of JB9969-1999.

十三、List of random attachments and supporting parts, technical document list

If you need a bending machine or are interested in a bending machine, please provide the plate material, plate thickness, and plate width (bending length) , and we will recommend a suitable bending machine model for you

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8615653328535

WhatsApp:+8615653328535 Wechat: +8615965331535

Wechat: +8615965331535  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com