一、 Brief introduction:

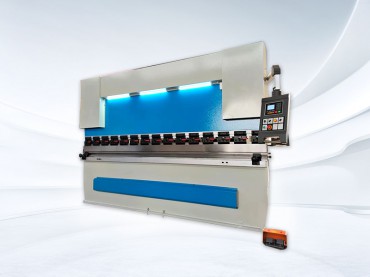

A bending machine is a device used to complete the overall bending and forming of sheet metal. Generally, after a single stroke of the slider, it can be bent into a certain geometric cross-section profile. If the mold is replaced and bent multiple times, various complex cross-sectional shapes can also be obtained.

In forging equipment, the bending machine has become one of the most popular metal forming equipment, and its application scope covers almost all industrial fields such as aviation, shipbuilding, railways, highways, mines, metallurgy, automobiles, home appliances, construction machinery, engineering machinery, agricultural machinery, light industry, instruments, electricians, etc

二、 Main technical parameters:

三、 Structural and performance characteristics:

(1) Electrohydraulic servo synchronous control system:

The electro-hydraulic servo synchronous control system mainly consists of a hydraulic system, a detection system, and an electrical control system. The hydraulic system includes a pump control block and a synchronization control block, which includes a filling valve, an electro-hydraulic proportional valve, a closed-loop control valve, and an electronic amplifier for the closed-loop control valve. Its function is to control the pressure of the hydraulic system, execute the up and down movement of the two oil cylinders, and the pressure can be infinitely adjusted between 0 and 30 MPa. The proportional flow valve port can be infinitely changed to ensure the synchronization of the two oil cylinders.

The detection system includes two incremental grating rulers and a signal amplifier. Its function is to detect the displacement at both ends of the slider and provide feedback to the electrical control system. On the one hand, it provides the position of the speed conversion point, and on the other hand, it provides the difference between the two ends.

The electrical control system is a specialized CNC system for German Alpha bending machines, with different models and varying levels of functionality. However, its most basic functions include controlling the opening of the electro-hydraulic proportional valve based on the feedback difference from the detection system to ensure synchronization between the two oil cylinders, and calculating the system pressure, slider positioning position, and material blocking positioning position based on programming parameters.

Due to the fact that the entire system is a world-renowned product, its reliability and accuracy are very high. Even in extreme load changes or single side load situations, the synchronization accuracy of the dual cylinder is less than 0.02mm, and its anti-interference ability is very strong.

The cost-effectiveness of this system is considerable when used in both high-precision parts and large tonnage situations.

(2) Electrohydraulic servo hydraulic positioning system:

Due to the fact that the synchronization accuracy of the electro-hydraulic servo synchronous bending machine is always controlled within 0.02mm, and its electro-hydraulic proportional flow valve can be completely closed, the final positioning of this bending machine can only be achieved by closing the oil inlet pressure of the two oil cylinders. Its positioning position is accurately guaranteed by a grating ruler, and the repeated positioning accuracy is not more than 0.02mm.

From the previous synchronous control characteristics and the current bending angle control characteristics, the mechanical part and oil cylinder structure of the electro-hydraulic servo synchronous bending machine are much simpler and easier to manufacture. Especially in large tonnage bending machines, this is more evident, so this type of bending machine is widely accepted by users.

(3) The positioning of the rear stopper adopts a CNC device.

(4) Action control of slider operation:

After adjusting the lower limit of the slider and the positioning of the rear stopper, it can be bent. The operation of the slider is achieved through the coordination of hydraulic and electrical systems. According to the characteristics of the bending process, the operating program of the slider is:

Top dead center, fast down, speed conversion point, work in, bottom dead center, pressure maintaining and relief, return trip.

When the oil ports in the upper and lower chambers are fully opened to open the fuel tank, the slider quickly descends under its own weight. At this time, the upper chamber is filled with oil from the fuel tank through the filling valve; After reaching the speed conversion point, the lower chamber oil port is changed to low-pressure closed, the filling valve is closed, and the upper chamber is a slowly descending folding plate of the oil pump inlet slide, called the work inlet; After reaching the bottom dead center, the slider stops moving downwards and the system maintains pressure; After the upper chamber is depressurized, return to complete one cycle.

四、 The process flow of the machine:

1. Shot blasting cleaning treatment of sheet metal:

Shot blasting cleaning has the following advantages:

(1) Improve the corrosion resistance of mechanical products and metal profiles

(2) Improve the fatigue resistance of steel and extend its service life

(3) Optimize the surface process status of steel

(4) Beneficial for CNC cutting machine cutting and precision cutting

(5) Due to the regular shape of the steel plate before processing, it is beneficial for mechanical rust removal and spray painting after final assembly

2. CNC cutting and cutting of steel plates:

3. Planing and milling of plate shaped parts

4. Welding and forming to perform aging vibration and eliminate internal stress

5. After annealing, the overall welded parts enter the processing process

6. Assembly, testing, folding, painting

五、 Technical characteristics and performance description:

1. The model is advanced and beautiful, with two oil cylinders fixed on the left and right wall panels. The overall force state of the machine is reasonable and the rigidity is sufficient.

2. The use of electro-hydraulic servo synchronization method ensures the synchronization of the oil cylinder, with good synchronization performance, strong anti bias load ability, and simple debugging. The two oil cylinder strokes Y1 and Y2 are controlled separately, and two grating rulers are equipped to detect the displacement of the slider. The positioning accuracy can reach 0.02mm, and the repeated positioning accuracy is 0.02mm.

3. The rear material is controlled by CNC.

Characteristics of DE-15 CNC System of German Alpha Company

8+1 axis 15 6-inch touch screen electro-hydraulic servo CNC system

Integrated solution

The DE15 system adopts a 15.6-inch full-color touch screen with a simple and easy to understand operation page, providing a more user-friendly design for the bending machine industry. In some industries that require high processing efficiency, various step changing conditions are provided, and flexible step changing methods result in a doubling of processing speed and efficiency.

Function Introduction:

1. Supports switching between angle programming and depth programming

2. Support mold library product library settings

3. Each step allows for free setting of the opening height

4. The position of the gear shift point can be freely controlled

5. Standard multi axis extensions for Y1, Y2, R, etc

6. Support mechanical compensation workbench control

7. Support for automatic generation of large arcs program

8. Support multiple step changing options such as top dead center, bottom dead center, loose foot, delay, etc., effectively improving machining efficiency

9. Supporting simple electromagnetic bridge

10. Support for fully automatic pneumatic drag material bridge function

11. Support automatic bending, achieve unmanned bending control, and support up to 25 steps of automatic bending

12. Support valve group configuration function, fast down, slow down, return, unloading action, and valve action time control

13. 200 product libraries with 25 steps, each product library name can be customized in both Chinese and English, and the large arc supports 99 steps

六、 1. Basic functions

·Adopting real-time Windows embedded operating system, it can achieve instant shutdown

·Fashionable exterior design, easy to operate, reflecting a people-oriented approach

·2D graphic programming

·Built in PLC function reduces circuit design and increases reliability

·USB interface

·Automatic accumulation of machine working time and bending times

·Automatic preparation of bending process

·Machine tool shape, mold, and workpiece can be freely scaled in a 1:1:1 ratio in a graphical manner

·Comprehensive collision detection function, eliminating waste products

·Error warning system to prevent misoperation

·Built in word processor

·Memory capacity 32MB

·Remote diagnostic function

·Metric/English conversion

·Multi machine linkage operation

·Multiple text displays including Chinese

·User Program Interface (USB)

2. Auxiliary functions

·Diagnostic program

·Help text, online help function

·X. Y-axis teaching

3. Option function

·Network interface

·Material support control

·Angle automatic correction sensor interface

·Barcode recognizer interface

·USB hard drive

4. Automatically calculate content

·Speed conversion point position

·Mold safety protection zone

·Clamping point position

·Bending force kN

·Matching between programming values and actual positioning values

·Bottom bending pressure

·Unfolded length

·Worktable deformation compensation

·Mold safety area

·Automatic calculation of large arcs

5. Interface

·The second serial interface required for PLC safety

七、 The main configuration of the electro-hydraulic servo bending machine is:

八、 Main technical parameters of electrical control system:

1) Power supply voltage: three-phase 380V AC -+10%

Frequency: 50Hz ± 1HZ

2) Operating environment temperature -20 to+50 ℃

Humidity 20-85% (non condensing, non condensing)

Altitude < 1000m

3) Protection level: Electrical control cabinet IP40

Control box IP45

If you need a cnc press brake or are interested in a cnc press brake, please provide the plate material, plate thickness, and plate width (bending length) , and we will recommend a suitable cnc press brake model for you

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8615653328535

WhatsApp:+8615653328535 Wechat: +8615965331535

Wechat: +8615965331535  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com